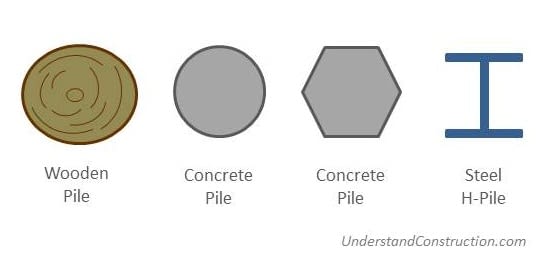

Pile foundations are normally required when the foundation load is too heavy for the soil to carry, or when building close to a body of water, or when building on soil with high volume change potential. They are formed by sinking long, slender, columnar elements typically made from steel or reinforced concrete, or sometimes timber.

Types of Materials Used in Pile Foundation

There are a variety of different materials that can be used in the piling process. Many people use wood, steel or concrete as their chosen piling materials. Naturally, the foundations of any building have to be exceptionally sturdy, so that’s why the choice of materials is important.

Concrete

Concrete piles are further divided into precast and cast in place concrete piles,

A. Precast Concrete

If the precast concrete pile are rectangular in shape, they are cast horizontally in the pile bed. Circular piles are usually cast vertically. To prevent breakage during mobilization from the casting bed to the foundation site, precast piles are normally reinforced with steel. After the piles have been cast, they must be cured according to the manufacturer’s requirements. After the piles are cast, curing has to be performed as per specification. Generally curing period for pre-cast piles is 21 to 28 days.

B. Cast in-place Concrete

This type of pile is constructed by boring of soil up to the desired depth and then, depositing freshly mixed concrete in that place and letting it cure there. This type of pile is constructed either by driving a metallic shell to the ground and filling it with concrete and leave the shell with the concrete or the shell is pulled out while concrete is poured.

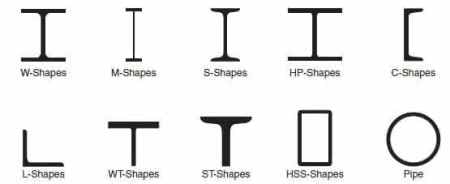

Steel

Steel piles are made of high-quality steel with a portion that is H, X, or thick pipes. They are ideal for long-distance handling and driving. Because of their limited cross-sectional area and high strength, they are easier to penetrate in firm soil. The size may vary from 10 inches to 24 inches in diameter and thickness is usually ¾ inches.

They can easily be cut off or welded together. There is a chance of corrosion if the pile is pushed into a soil with a low pH value. In permanent works, tar coating or cathodic shielding may be used to prevent corrosion.

Timber

In the past, timber piles were used. Given the lack of timber wood these days, the use of pile foundations is significantly reduced. Long cohesion piling and piling under embankments are best done with timber. The timber should be in good shape and should not have been infested with insects.

Timber piles are placed under water level. They last for approximately about 30 years. They can be rectangular or circular in shape. Their diameter or size can vary from 12 to 16 inches. The length of the pile is usually 20 times of the top width.

They are usually designed for 15 to 20 tons. Additional strength can be obtained by bolting fish plates to the side of the piles.

Composite Pile

Composite pile such as Plastic piles are used in special applications such as in marine environments and within soil zones exposed to seasonal changes.

How does Piling work?

Piling is a method of burying large quantities of wood, steel, or concrete in the soil. The deep insertion of these elements ensures a more secure basis for the construction project.

Consider what would happen if your office building didn’t have a solid foundation under it. It wouldn’t last long! People don’t really realize how much planning, measuring, and hard labor goes into building projects, but as any contractor can tell you, there’s a lot of it. Piling is not a technique that we can all pick up in a few hours; it is a highly skilled task that is extremely necessary. To ensure that the building is as solid as a brick, make sure the foundation is solid and the piling is done correctly.

However, the piling process can not begin until other important factors have been taken into consideration like the condition of the soil beneath the ground. For example, wet soil is not a good consistency for which to place any wood, metal or steel in as part of your piling work.